Successful mining operations that lead to increased profit margins and minimal losses is dependent on efficient investment and efficient mining practices.

Advancements in climate change conditions the world over and the negative impact of mining operations in their immediate environment places a moral responsibility in mining companies to adopt environmentally friendly, cost effective, and efficient ways of doing business.

Transporting ore and tailings in mines have depended solely on the use of trains and heavy duty trucks in the past. These methods of transportation are dependent on the use of coal and diesel as fuel. The fuel emits poisonous particles into the atmosphere, affecting the health of workers, plants and water bodies in surrounding communities. The use of trucks also raises dust into the atmosphere, affecting air quality and exposing workers and members of the immediate community to serious health conditions.

The need for an environmentally friendly, cost effective and efficient way of transporting ore and tailing is long overdue. The use of slurry pipes to move ore and tailing is one of the most efficient, cost-effective and environmentally friendly mediums of transportation in mines.

Slurry pipes transportation involves the process of mixing ore/tailing with water so that they can easily be moved in short and long distant pipelines to final destinations. The hydrotransport system uses high pressure water to move the products.

The hydrotransport pipeline method of transporting ore/tailings in mines combines a number of handling benefits with minimal maintenance and low environmental impact.

Challenges of Slurry Pipe Transportation

The most important challenge that affects effective and efficient hydrotransport in mines is pipeline obstruction by sanding. This occurs when sediments build-up in pipes, causing a blockage that reduces the smooth movement of materials. A pipeline sanding can result in a lower flow rate and higher discharge pressure that can affect productivity and revenue negatively.

HPE Solutions

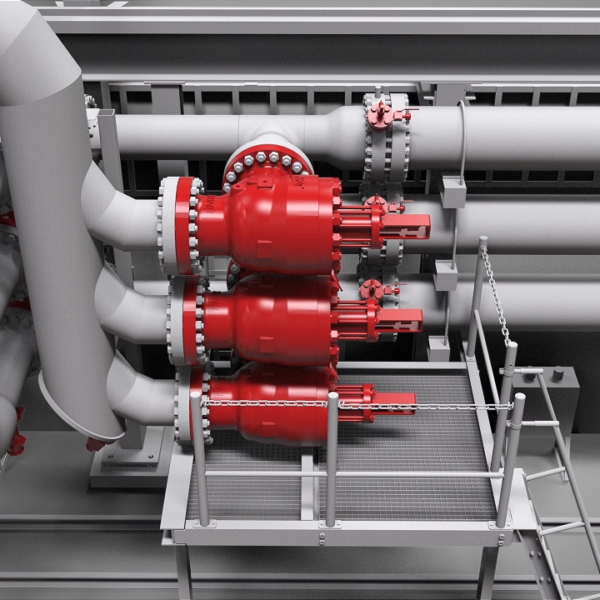

3 Chamber Pump System (3CPS)

The 3 Chamber Pump System is an energy efficient recovery pump designed for optimal performance in ensuring that the energy pressure of water entering pipelines are adequately recovered and used to pump slurry efficiently.

HPE’s 3CPS also has an exceptional energy saving feature which operates by pumping slurry while allowing conventional dewatering pumps to be switched off most of the time.

Electric Control Actuator

The HPE Electric Control Actuator is a special innovation, designed to provide accurate PLC control over valve position. It operates by protecting slurry pumps and pipelines against any damage that may result due to the start/stop or flow surging caused by an electrical trip out by minimising pressure surge. This is done by gradually increasing or decreasing the velocity of water.

Filtration

HPE Filtration unit operates by ensuring that sediments do not collect on the beds of pipelines. This feature protects your pipeline from blockage and from potential explosion. In so doing, the safety of workers is assured and the risk of a total pipeline blockage is removed.

For the best mining solutions that ensures eco-friendly mining operations, HPE is your best choice.

Contact HPE for all your productive mining needs.

Location: 19 Precision Street, Kya Sand, Randburg, South Africa, 2194

Telephone: +27 11 462 1903

Email: [email protected]